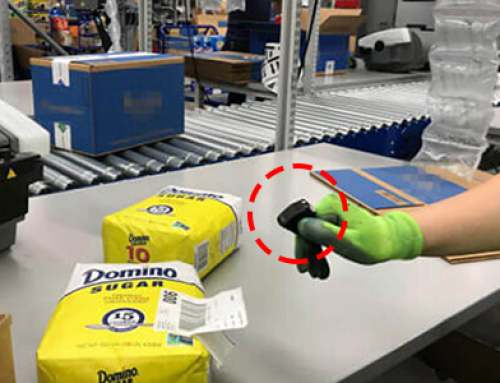

In the fast-paced environment of a pharmaceutical warehouse, efficiency and accuracy are crucial. The manual picking process directly impacts the speed and reliability of drug distribution. HYCO’s ring scanner, equipped with continuous scanning functionality, revolutionizes this process by enhancing efficiency, accuracy, and compliance with GSP guidelines.

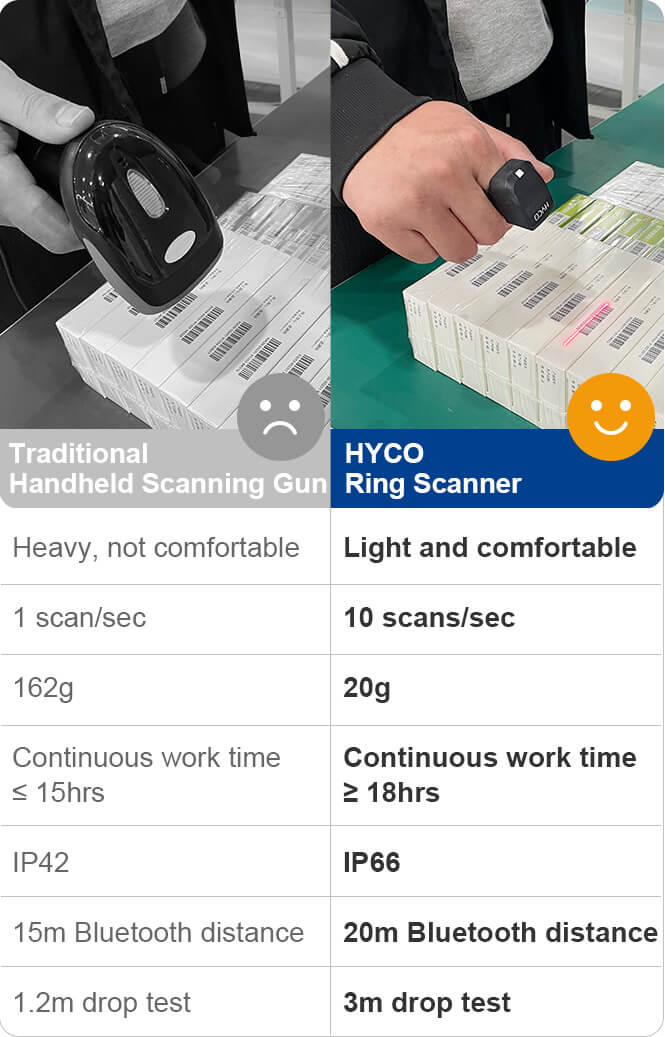

The HYCO Ring Scanner‘s continuous scanning mode allows for scanning at a rate of 10 times per second, resulting in a 5 to 10 times increase in efficiency compared to traditional hand-held scanners. This significantly reduces human resource costs associated with code scanning, shortens scanning time, and promotes the adoption of drug safety monitoring systems based on drug supervision codes.

Speed and Efficiency in Picking Operations

Hands-Free Operation:

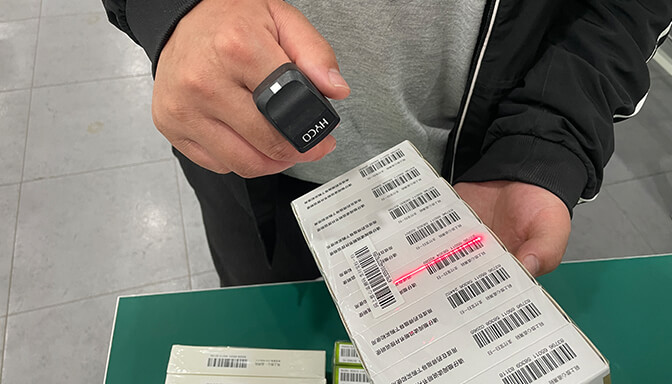

HYCO’s ring scanner is designed to be worn on the finger, freeing workers’ hands for seamless picking and scanning. This hands-free approach eliminates the need to constantly pick up and put down a handheld scanner, streamlining the picking process and allowing workers to move swiftly through their tasks.

Continuous Scanning Capability:

The standout feature of HYCO’s ring scanner is its ability to scan multiple drug regulatory codes in quick succession without pausing. This is especially advantageous in high-volume environments where large quantities of items need to be processed quickly. Workers can scan numerous items in one fluid motion, drastically reducing the time required for each order.

Real-Time Data Capture:

As items are scanned, data is instantly transmitted to the warehouse management system (WMS), ensuring inventory levels are updated in real-time. This minimizes delays, keeps inventory records accurate, and enhances overall operational efficiency.

Improved Accuracy and Precision

Error Reduction:

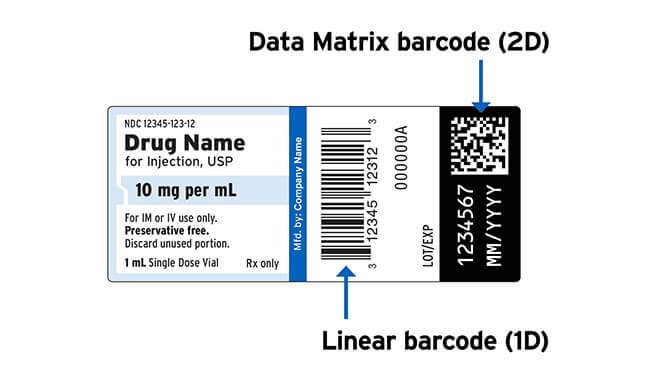

Manual data entry errors can be costly and time-consuming to correct, particularly in the pharmaceutical industry where precision is vital. HYCO’s ring scanner automates the data capture process, significantly reducing these errors. Each scanned item is accurately recorded, ensuring the correct products and quantities are picked.

Verification:

The scanner verifies that the right items are picked by cross-referencing scanned barcodes with the order details in the WMS. This verification is crucial for maintaining the integrity of pharmaceutical products and complying with stringent regulatory standards.

Enhanced Workflow and Productivity

Guided Picking:

Integrated with a WMS, HYCO’s ring scanner can direct workers to the exact location of items, optimizing their picking route and reducing unnecessary travel time within the warehouse. This guided picking functionality ensures that workers follow the most efficient path, further speeding up the picking process.

Batch and Wave Picking:

The continuous scanning feature supports efficient batch and wave picking methods. Workers can handle multiple orders simultaneously, scanning and sorting items quickly. This capability is particularly beneficial in high-demand periods, increasing overall throughput and productivity.

Superior Inventory Management and Traceability

Real-Time Inventory Updates:

The continuous scanning function ensures inventory levels are updated instantly as items are picked. This real-time visibility into stock levels helps maintain accurate inventory records, essential for effective inventory management and planning.

Detailed Traceability:

In the pharmaceutical industry, traceability is vital. HYCO’s ring scanner captures comprehensive information, including batch numbers, expiration dates, and lot numbers. This ensures every item can be tracked throughout the supply chain, supporting compliance with GSP and other regulatory requirements.

Improved Ergonomics and Worker Satisfaction

Comfort and Reduced Fatigue:

The ergonomic design of HYCO’s ring scanner makes it lightweight and comfortable to wear for extended periods. By reducing the physical strain associated with repetitive scanning tasks, it helps prevent worker fatigue and injuries, contributing to a safer and more comfortable working environment.

Ease of Use:

The scanner’s user-friendly interface, featuring simple controls and intuitive feedback mechanisms (audible, visual, and haptic), ensures that workers can quickly adapt to using it. Minimal training is required, and workers can start benefiting from the scanner’s advanced features almost immediately.

Compliance and Quality Control

Regulatory Compliance:

Ensuring compliance with GSP and other regulatory standards is crucial for pharmaceutical warehouses. HYCO’s ring scanner helps maintain compliance by capturing and accurately recording detailed product information. This robust data capture supports thorough documentation and traceability, essential for meeting regulatory requirements.

Quality Assurance:

The scanner’s ability to continuously scan and verify multiple items ensures that only high-quality, compliant products are distributed. This rigorous quality control process minimizes the risk of errors and ensures that customers receive the correct medications.

Summary

HYCO’s ring scanner, with its continuous scanning functionality, offers transformative advantages for the manual picking process in pharmaceutical warehouses. Its hands-free operation, real-time data capture, and continuous scanning capability significantly increase speed and efficiency. By reducing errors, enhancing workflow, and ensuring compliance with GSP standards, HYCO’s ring scanner helps warehouses maintain high-quality operations and deliver accurate, reliable service to their customers.

In an industry where precision and efficiency are critical, HYCO’s ring scanner stands out as an essential tool for optimizing warehouse operations, enhancing productivity, and ensuring the safe and effective distribution of pharmaceutical products.